Motors

Motors are essential components in automation, robotics, and industrial applications, converting electrical energy into mechanical motion. They come in various types, each designed for specific functions and precision levels. Common motor types include AC motors, servo motors, stepper motors, and linear motors, each offering unique advantages in terms of speed, accuracy, and control.

Motor Types/Options

AC Motors

AC motors operate using alternating current (AC) and are widely used in industrial and commercial applications due to their reliability and efficiency. They come in two main types: synchronous and asynchronous (induction) motors. Induction motors are common in HVAC systems, pumps, and conveyors, while synchronous motors are used in applications that require precise speed control.

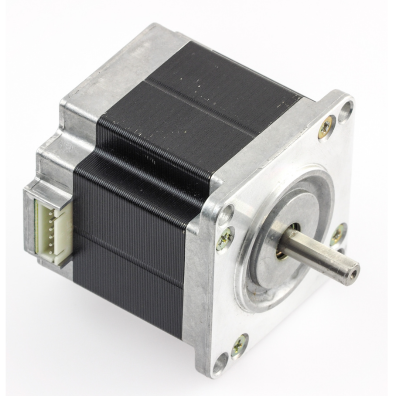

Stepper Motors

Stepper motors move in discrete steps, offering high positional accuracy without needing feedback systems. They are commonly used in 3D printers, CNC machines, and camera gimbals. Their ability to hold position makes them great for applications requiring stability and repeatability, although they may lack the speed and torque of servo motors.

Servo Motors

Servo motors are highly accurate and provide closed-loop control, making them ideal for robotics, CNC machinery, and high-precision automation. They consist of a motor, feedback encoder, and control system, ensuring precise positioning and speed adjustments. Servo motors can handle dynamic loads and are commonly used in robotics and industrial automation.

Linear Motors

Linear motors differ from traditional rotary motors by generating direct linear motion instead of rotational motion. They are used in high-speed manufacturing lines, semiconductor equipment, and advanced robotics. Without gears or mechanical linkages, linear motors offer frictionless movement and high acceleration.

Compare & Contrast Motor Types

| Motor Type | Precision | Speed | Torque | Voltage Range | Typical RPM | Common Applications |

|---|---|---|---|---|---|---|

| AC Motor | Moderate | High | High | 110-480V AC | 1,000 – 3,600 RPM | HVAC, conveyors, pumps |

| Servo Motor | High | High | High | 24-480V AC/DC | Up to 6,000 RPM | Robotics, CNC, automation |

| Stepper Motor | Very High | Moderate | Moderate | 12-48V DC | 200 – 1,200 RPM | 3D printers, CNC, positioning systems |